Continuous improvement (CI), if implemented well, stands viable for the manufacturing industry to improve its operational efficiency, productivity, and customer satisfaction on a high level.

What Is Continuous Improvement?

Continuous improvement is a systematically-organized and ceaseless practice of ensuring incremental improvement or breakthrough success in products, services, or processes within an organization.

Based on the approach called Kaizen, continuous improvement methodologies serve the goal of keeping the products or services or business processes improved or in continuous refinement.

Key Pointers About Continuous Improvement Methodologies

- It is a ceaseless approach to improve the productivity or operational efficiency of a business in terms of its products, services, or processes.

- A well-implemented CI approach adds value to the products, the services, or the processes in your business

- For a CI to result in accurate improvements, it seeks to rely on employees’ feedback or inputs.

- The efficacy of CI also hinges on your team’s dedication to the process

- It aims to focus on those activities that drive valuable results for customers while eliminating redundant processes

Key Elements To Consider When Implementing Continuous Improvement

- Identify The Most Crucial Goal That Matters For Your Business

While this may sound like a self-explanatory suggestion, yet its significance lies in the fact that when you adopt CI in your business, you need to start with a goal consistent with your business strategy.

You can’t risk the cluelessness of what you are targeting. Moreover, avoid changing things just because you want to justify the transition. If you ask any company offering product development services, you will get that the goal of continuous improvement is to improve those areas that matter a lot for your strategic goals.

- Work On The Methods That Can Support The Goal

The methodologies of CI should mean valuable in terms of guidance and the necessary roadmap to achieve your targeted results. So, you need to identify whether you have these metrics in place. If yes, you will find it easy to stay focused on your goal.

- Utilize The CI Tools Actualize Your Methods

To make continuous improvement successful, you can take resort to a wide variety of tools and techniques. Make the most of your chosen tool or technologies based on the current state or future of your goals.

For example, Toyota used its own methods and tools to become a market leader. However, the achievement of the feat cost them many years of perseverance.

Hiring a reputed software development company is worth considering in this context. That’s because it will help you as a business to understand CI methodologies and choose the best one aligned with your business goals.

Benefits Of Continuous Improvement Approach

- It removes or reduces waste, makes product quality better

- It drives efficiencies and optimizes labor productivity

- Helps the manufacturing industry fix issues associated with delivery schedules and customer relations

- Improves product quality which leads to improved customer satisfaction

Adoption Of Continuous Improvement Methodologies

- Lean

The main objective of lean as a management system is to render maximum customer satisfaction. For this, it maximizes value while reducing the waste in the process that was used to create the value.

Lean works on different philosophies, tools, and methods to boost people’s engagement on all levels in understanding and solving problems within a company.

The way of working and methods of Lean was adopted by the Toyota Motor Company, the world’s greatest motor manufacturing company. The lean methodology first came into being from the book titled The Machine That Changed The World by James Womack in 1991.

- Six Sigma

One of the most famous continuous improvement methodologies, six sigma promotes quality control methodology intended to reduce or eliminate problems or defects in manufacturing.

First introduced by Bill Smith, in 1986, six sigma made inroads into the limelight when it was popularized by Jack Welch, the former CEO of General Electric. Jack implemented six sigma quality control in General Electric. Five years down the line, the company witnessed reported savings of $12 billion.

Six Sigma centralizes around the core belief of boosting product quality and customer satisfaction, something that Jack Welch adopted and pioneered excellence for GE.

- Total quality management (TQM)

TQM is one of the most popular continuous improvement methodologies that involve people’s participation in the improvements of processes, services, and product quality. The purpose of this methodology stems from the core belief of rendering customer satisfaction.

Key elements of TQM:

- Customer-focused quality

- Absolute participation or engagement of employees with a common goal of serving customers

- Process-oriented improvement

- Cross-functional collaboration

- Effective communications

- Data-driven decision making

- Continuous improvement to satisfy stakeholders

- ISO

The ISO 9000 Series defines overall quality management standards. These standards regulate the structure, fundamentals, and definitions of a company’s quality management system.

ISO is maintained by the International Organization of Standardization and is designed to set up a quality management system for companies of different sizes.

Like TQM, it also has its core principles, such as –

- Customer-focused approach to meet and exceed customer needs

- Motivational leadership direction that favors constant progress

- People’s engagement to fulfill the company’s goals

- Process approach to establish measures and prioritize improvements

- Data-based decision making

- Collaborative, relationship management

- Theory of Constraints

Theory of Constraints (ToC), as a continuous improvement methodology, treats business systems as a series of nodes restrained by bottlenecks and solves them to maximize business outputs. The methodology seeks to reduce costs and inventory in conjugation with the data of market demand.

ToC-driven improvements result in a business system that attempts to achieve an equilibrium between supply and demand and then works to reduce expenses and inventory.

- Agile

One of the most popular continuous improvement methodologies, agile finds its application in software development and project management spaces.

The goal for which it is designed is to improve the value of resources used by rendering the greatest possible impacts in the least time-consuming manner.

Generally, the method is optimized for highly innovative types of tasks and is being used in operations requiring a greater level of flexibility and adaptiveness.

- Learn startup

This CI methodology is used to develop and make available a new range of products to the market with a focus resting on building technology-oriented products. It works on the principle of building businesses and products to reduce the product development cycle and discover the viability of a projected business model.

- Growth hacking

This is a method that attempts to apply the scientific method to achieve customer acquisition and conversion. It also helps companies to scale faster. To put it in a simple way, growth hacking is all about setting a focused target and then experimenting with ways to achieve it.

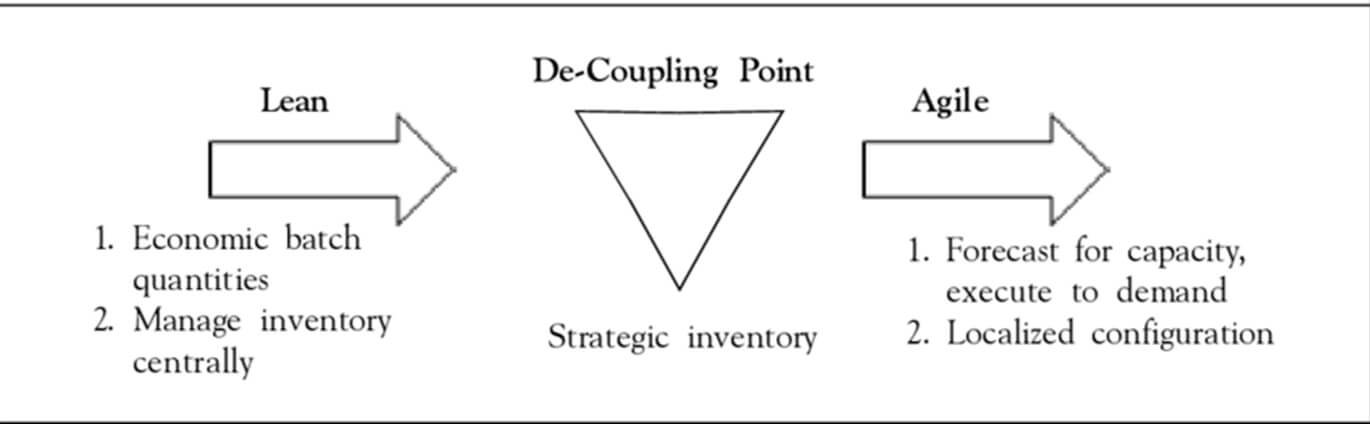

- Leagile

It is a hybrid methodology that combines both agile and lean methodologies to develop the supply chain market cost-effectively. To say otherwise, Leagile strategy works with the core focus on obtaining flexibility and competitiveness cost-effectively.

- Lean Six Sigma

It is an approach that seeks to improve processes in a collaborative team effort. The goal is to make performance highly improved through the methodological removal of operational waste and mitigation of process variation.

For organizations, using lean six sigma is beneficial in terms of improving employee and business performance. The underlying motive behind this method is to establish a clear path for achieving improvement goals and improving output quality by eliminating product-related issues.

Closing Statements

As you may have gone through the above pointers, you can conclude that there are many continuous improvement methodologies that a business can adopt to transpire operational efficiencies, including software development services. Based on the suggestions, choose the methodology best suited to your business development journey.

In fact, considering how businesses are evolving over time, it is recommended to keep an eye on how processes are evolving and what you can do for optimal business results, including leveraging software development services. Adopting CI methodologies, therefore, is giving your business timely assistance for greater efficiency.

Hiring one of the best product development companies that offer software development services is a safe recommendation you consider. That’s because it will help you with the opportunity of working with a reputed software development partner with experience in CI methodologies.