High-performance conveyor belts are crucial for modern industrial operations, offering enhanced durability, strength, and flexibility. These belts improve operational efficiency by reducing maintenance needs, lowering energy consumption, and providing reliable performance in harsh environments. They are well-suited for long-distance material handling and high lifts, ensuring smooth and efficient transport of materials. For instance, a mining conveyor belt can handle the heavy loads and extreme conditions of mining environments, ensuring continuous and efficient operation. With features like fire resistance and anti-static properties, they also enhance workplace safety. High-performance conveyor belts are a smart investment for any industry, providing long-term cost benefits and supporting sustainable practices.

Overview of High-Performance Conveyor Belts

Introduction to the Growing Needs for Durable Conveyor Systems

In today’s industrial landscape, the demand for efficient and reliable material handling systems is greater than ever. As industries such as mining, manufacturing, and logistics expand, the volume of materials being transported has increased significantly. This surge in material handling requirements has driven the need for more durable and high-performing conveyor systems. These systems are essential for maintaining productivity, ensuring safety, and reducing operational costs in various industrial applications.

Industrial Expansion and Increased Material Handling

With the expansion of industries, the scale of operations has grown, necessitating the transport of larger quantities of materials over greater distances.

Industries such as mining, agriculture, and construction rely heavily on conveyor systems to move raw materials and finished products efficiently.

The rise of e-commerce and automated warehouses has also contributed to the growing demand for reliable conveyor systems to handle high volumes of goods.

Challenges in Conventional Conveyor Systems

Traditional conveyor belts often face issues such as wear and tear, belt slippage, and breakdowns, leading to frequent maintenance and downtime.

The harsh environments in which these belts operate, including exposure to abrasive materials, extreme temperatures, and heavy loads, exacerbate these challenges.

Inefficiencies in conventional systems can result in significant operational delays and increased costs, impacting overall productivity.

Technological Advancements Driving Demand

Advances in material science and engineering have led to the development of high-performance conveyor belts designed to meet the rigorous demands of modern industries.

Innovations such as smart conveyor systems with integrated sensors and automation capabilities are becoming increasingly popular, offering enhanced monitoring and control.

The shift towards sustainability has also driven the demand for energy-efficient and environmentally friendly conveyor systems.

Importance of High-Performance Conveyor Belts

High-performance conveyor belts are integral to the efficient and safe operation of material handling systems across various industries. These advanced belts offer numerous benefits that address the limitations of conventional conveyor systems, providing significant improvements in durability, efficiency, and overall performance.

Enhanced Durability and Longevity

High-performance conveyor belts are engineered with superior materials such as high-tensile steel cords, advanced polymers, and heat-resistant compounds.A steel cord conveyor belt, for instance, provides exceptional resistance to wear, abrasion, and extreme temperatures, extending the lifespan of the belts and reducing the need for frequent replacements.

These materials provide exceptional resistance to wear, abrasion, and extreme temperatures, extending the lifespan of the belts and reducing the need for frequent replacements.

The robust construction of these belts ensures they can withstand heavy loads and continuous operation in demanding environments.

Increased Operational Efficiency

High-performance conveyor belts minimize downtime by reducing the frequency of maintenance and repairs required.

The improved reliability and efficiency of these belts lead to smoother and faster material handling processes, enhancing overall productivity.

Features such as reduced rolling resistance and optimized belt designs contribute to lower energy consumption, resulting in cost savings.

Safety and Compliance

High-performance conveyor belts are designed to meet stringent safety standards, ensuring the protection of workers and equipment.

Features such as fire resistance, anti-static properties, and enhanced grip surfaces help prevent accidents and hazards in the workplace.

The use of these advanced belts supports compliance with industry regulations and promotes a safer working environment.

Versatility and Adaptability

High-performance conveyor belts are suitable for a wide range of applications, from mining and quarrying to food processing and packaging.

Their adaptability allows them to be customized to meet specific operational requirements, including various belt widths, lengths, and configurations.

The ability to integrate with existing systems and accommodate future expansions makes these belts a versatile solution for evolving industrial needs.

Sustainability and Environmental Benefits

The durability and efficiency of high-performance conveyor belts contribute to reduced waste and resource consumption.

Energy-efficient designs and materials help lower the environmental impact of industrial operations.

The development of eco-friendly conveyor belts made from recyclable or biodegradable materials further supports sustainability initiatives.

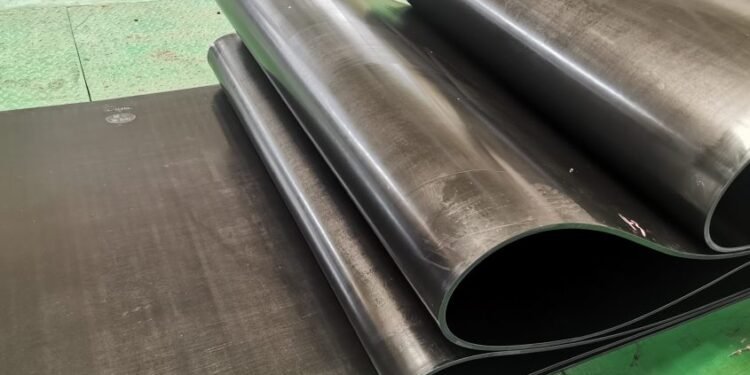

Strength and Durability

Advantages of Using High-Performance Materials in Conveyor Belts

Enhanced Tensile Strength

High-performance materials such as high-tensile steel cords, Kevlar®, and advanced polymers provide superior tensile strength compared to traditional materials.A nylon conveyor belt, for instance, allows conveyor belts to handle heavier loads and more rigorous operating conditions without compromising their structural integrity.

These materials allow conveyor belts to handle heavier loads and more rigorous operating conditions without compromising their structural integrity.

Enhanced tensile strength ensures that the belts can transport large volumes of material over long distances efficiently and reliably.

Resistance to Wear and Tear

High-performance conveyor belts are designed to resist wear and tear from abrasive materials, reducing the frequency of maintenance and replacements.

Materials like polyurethane and high-density polyethylene (HDPE) offer excellent resistance to abrasion, ensuring that the belts maintain their surface integrity even under harsh conditions.

This resistance extends the service life of the conveyor belts, leading to cost savings and reduced operational downtime.

Chemical and Corrosion Resistance

In industries such as chemical processing, food processing, and mining, conveyor belts are often exposed to corrosive substances.

High-performance materials are resistant to a wide range of chemicals, oils, and solvents, preventing degradation and maintaining the belt’s functionality.

This chemical resistance is crucial for maintaining the integrity and performance of the belts in harsh environments, ensuring consistent operation and safety.

Temperature Tolerance

High-performance conveyor belts are capable of withstanding extreme temperatures, both high and low, without losing their mechanical properties.

Materials like heat-resistant rubber compounds and specialty fabrics maintain their flexibility and strength in high-temperature environments, such as foundries and metal processing plants.

Conversely, these materials also perform well in low-temperature conditions, making them suitable for cold storage and refrigerated transportation.

Impact and Shock Absorption

Conveyor belts made from high-performance materials can absorb and dissipate the energy from heavy impacts and shocks.

This capability is particularly important in industries where heavy and irregularly shaped materials are transported, such as mining and quarrying.

The improved impact resistance reduces the risk of damage to the belt and associated equipment, enhancing the overall durability and reliability of the conveyor system.

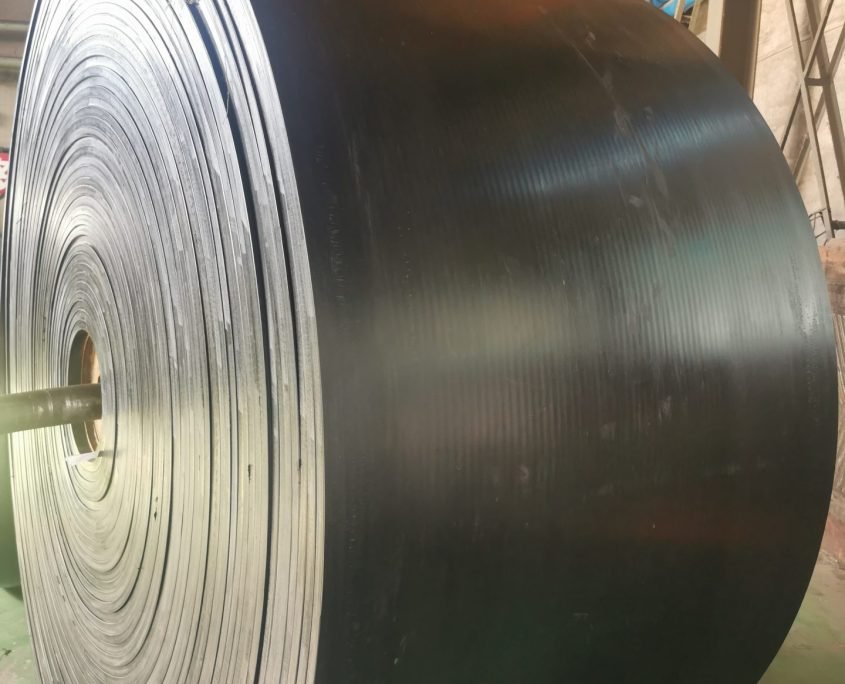

Greater Strength and Lower Elongation Benefits

Maintained Structural Integrity

High-performance conveyor belts exhibit lower elongation under load, which means they maintain their shape and structural integrity during operation.

Lower elongation reduces the risk of belt stretching, which can cause misalignment, slippage, and increased wear on the belt and other components.

Maintaining structural integrity is essential for ensuring the smooth and efficient operation of the conveyor system, minimizing disruptions and downtime.

Consistent Performance

The greater strength and lower elongation of high-performance conveyor belts ensure consistent performance, even under varying load conditions.

This consistency is crucial for industries where precise material handling and timing are essential, such as automated manufacturing and assembly lines.

Reliable performance reduces the need for frequent adjustments and recalibrations, enhancing the overall efficiency of the conveyor system.

Extended Service Life

The durability and strength of high-performance materials extend the service life of conveyor belts, reducing the need for frequent replacements.

Extended service life translates to lower long-term costs for maintenance and replacements, providing a better return on investment for industrial operations.

Longer-lasting conveyor belts also contribute to sustainability efforts by reducing material waste and resource consumption.

Increased Load Capacity

Conveyor belts made from high-performance materials can handle increased load capacities without compromising their performance or durability.

This increased load capacity allows for more efficient material handling, improving productivity and throughput in industrial processes.

The ability to transport heavier loads also reduces the number of trips required, further enhancing operational efficiency and reducing energy consumption.

Safety and Reliability

High-performance conveyor belts provide enhanced safety and reliability, reducing the risk of belt failures and accidents.

The robust construction and resistance to stretching and deformation ensure that the belts operate safely under high-tension conditions.

Reliable conveyor belts contribute to a safer working environment by minimizing the risk of sudden failures and ensuring the smooth and predictable movement of materials.

Reliable Performance conveyor belts

Cost-Effectiveness and Reliable Performance in Long-Distance Material Handling

Operational Efficiency

High-performance conveyor belts contribute significantly to operational efficiency by enabling continuous and reliable material transport over long distances.

The durability and low maintenance requirements of these belts minimize downtime, ensuring that operations can run smoothly without frequent interruptions for repairs or replacements.

Efficient material handling reduces the time and labor required for manual handling, leading to cost savings and increased productivity.

Lower Energy Consumption

Advanced materials and design innovations in high-performance conveyor belts reduce rolling resistance, which in turn lowers energy consumption.

Reduced energy usage not only cuts operational costs but also minimizes the environmental impact of industrial operations.

Energy-efficient conveyor systems are particularly beneficial in large-scale operations where long distances and continuous use can lead to significant energy expenditures.

Minimal Maintenance Costs

The superior durability and resistance to wear and tear of high-performance conveyor belts result in lower maintenance costs over time.

These belts require fewer replacements and less frequent maintenance, translating to long-term cost savings.

Predictive maintenance technologies integrated into modern conveyor systems help identify potential issues before they lead to costly breakdowns, further reducing maintenance expenses.

Extended Lifespan

High-performance conveyor belts are designed to withstand harsh operating conditions and heavy usage, leading to an extended service life.

The longer lifespan of these belts means that companies can amortize their investment over a more extended period, enhancing cost-effectiveness.

Extended service life also reduces the environmental impact by decreasing the frequency of belt replacements and the associated material waste.

Suitability for Long Conveying Distances and High Lifts

High Tensile Strength

High-performance conveyor belts, especially those reinforced with steel cords or advanced synthetic fibers, offer high tensile strength that can support the heavy loads required for long-distance conveying.

This strength ensures that the belts can transport materials over vast distances without stretching or deforming, maintaining consistent performance.

Efficient Material Flow

Conveyor belts designed for long-distance transport are engineered to handle high volumes of material efficiently, reducing bottlenecks and ensuring a smooth flow.

The ability to transport large quantities of materials in a single trip enhances productivity and operational efficiency, particularly in mining, quarrying, and large-scale manufacturing operations.

Capability to Handle High Lifts

High-performance conveyor belts are suitable for applications involving high lifts, such as those found in mining operations where materials need to be transported from deep within the earth to the surface.

The belts are designed to maintain stability and strength when transporting materials vertically or at steep inclines, ensuring safe and efficient handling of heavy loads.

The use of advanced materials ensures that the belts can withstand the increased tension and pressure associated with high lifts, preventing failures and maintaining operational reliability.

Resistance to Harsh Environmental Conditions

Conveyor belts used in long-distance and high-lift applications are often exposed to harsh environmental conditions, including extreme temperatures, moisture, and abrasive materials.

High-performance belts are designed to resist these conditions, ensuring reliable performance and longevity even in the most demanding environments.

This resistance reduces the likelihood of belt damage and the associated maintenance and replacement costs, enhancing overall cost-effectiveness.

Versatile Applications

High-performance conveyor belts are versatile and can be used in various industries, including mining, construction, logistics, and agriculture.

Their ability to handle long distances and high lifts makes them suitable for a wide range of applications, from transporting raw materials in mines to moving finished products in distribution centers.

This versatility ensures that companies can invest in conveyor systems that meet their specific needs while providing reliable and efficient performance.

The Role of High-Performance Conveyor Belts in Industrial Operations

The Benefits and Importance of High-Performance Conveyor Belts in Modern Operations

High-performance conveyor belts are integral to the efficiency and productivity of modern industrial operations. Their numerous benefits and vital role in material handling systems underscore their importance:

Enhanced Durability and Longevity

High-performance conveyor belts are constructed from advanced materials that offer exceptional durability and resistance to wear and tear. This results in a longer lifespan and reduces the frequency of replacements, leading to significant cost savings over time.

Superior Strength and Flexibility

These belts are designed to handle heavy loads and withstand high tension without stretching or deforming. The superior tensile strength and flexibility ensure that the belts maintain their performance even under demanding conditions, contributing to uninterrupted operations.

Operational Efficiency

The incorporation of high-performance materials and innovative design elements reduces rolling resistance, leading to lower energy consumption. This efficiency not only cuts operational costs but also supports sustainability by minimizing the environmental impact.

Minimal Maintenance Requirements

The robust construction of high-performance conveyor belts reduces the need for frequent maintenance and repairs. This results in less downtime and allows for continuous, reliable operation, enhancing overall productivity.

Adaptability to Harsh Environments

High-performance belts are engineered to resist extreme temperatures, moisture, chemicals, and abrasive materials. This adaptability ensures reliable performance in a wide range of industrial environments, from mining and quarrying to manufacturing and logistics.

Cost-Effectiveness

Despite the initial investment, high-performance conveyor belts offer long-term cost benefits through reduced energy consumption, lower maintenance costs, and extended service life. The overall cost-effectiveness makes them a smart investment for any industrial operation.

Safety and Reliability

Advanced materials and design innovations improve the safety and reliability of high-performance conveyor belts. Features such as fire resistance, anti-static properties, and impact absorption contribute to a safer working environment and reduce the risk of accidents and injuries.

Meeting the Challenges of Long-Distance Material Handling with Robust and Efficient Operation

High-performance conveyor belts are specifically designed to meet the unique challenges associated with long-distance material handling. Their robust construction and efficient operation address several critical aspects:

Handling Long Distances

High-performance belts are ideal for transporting materials over long distances. Their high tensile strength and resistance to elongation ensure that they can maintain consistent performance without stretching or degrading, even when conveying materials across vast distances.

Managing High Lifts

These belts are well-suited for applications involving high lifts, such as transporting materials from deep within mines to the surface or moving goods up steep inclines. Their structural integrity and strength enable them to handle the increased tension and pressure associated with vertical or inclined transportation.

Ensuring Smooth Material Flow

The superior design of high-performance conveyor belts enhances their troughability, ensuring that materials are securely contained within the belt and transported smoothly. This reduces the risk of spillage and ensures efficient material handling, even under heavy loads.

Adapting to Harsh Conditions

The ability to withstand extreme temperatures, abrasive materials, and chemical exposure makes high-performance belts ideal for demanding environments. This resilience ensures that the belts can operate effectively in challenging conditions, maintaining reliability and performance.

Optimizing Operational Efficiency

By reducing rolling resistance and energy consumption, high-performance conveyor belts enhance the overall efficiency of material handling operations. Their low maintenance requirements and extended service life further contribute to cost savings and operational continuity.

Improving Safety and Reducing Risks

High-performance belts incorporate safety features such as fire resistance and anti-static properties, which are crucial for operations in hazardous environments. These features help prevent accidents and ensure a safer working environment for employees.