Evolving gradually since the 18th century in the USA and Europe, it took several decades for pipe threading taps to adopt the modern mechanized system from the olden manual process.

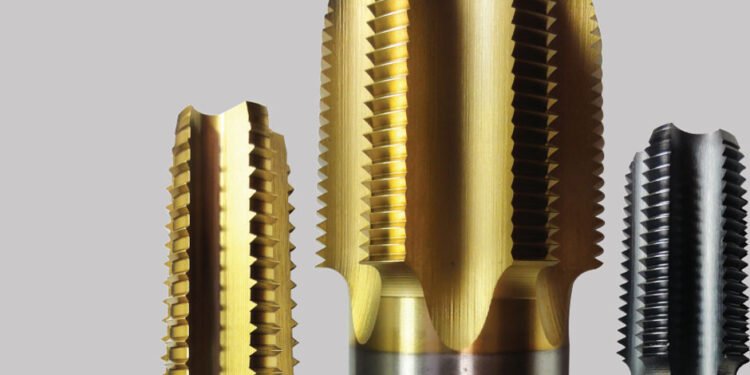

Functionality-wise, a pipe threading tap creates a thread on the inside surface of a hole. In other words, it cuts the pipe systematically.

According to recent market research, the global demand for cutting pipe and perforating pipe drilling tools is rising globally. The market study group Market Research Future recently submitted its report on the demand trend. The report says that the Cutting Pipe and Perforating Pipe Drilling Tools Market industry is projected to grow from USD 6.10 billion in 2022 to USD 9.8 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 4.5% during the forecast period (2023–2030).

What’s New In Threading Taps

The transformation of threading taps from a manual process to a modern mechanized one offers us a very interesting study. This evolutionary process was quite long.

In modern times, the machined pipe threading is generally carried out by the use of the following:

- Lathe machine

- Radial drilling machine

- Bench-type drill machine

- Pillar-type drill machine

- Vertical milling machine

- HMCs

But it took several centuries to devolve into the mechanized systems from the manual ones. In the golden days, when it was carried out manually, the risk of human error always remained. But this factor of human error has been eliminated by the use of machines.

From Manual to Modern Pipe Threading Taps: Phase-wise Evolution

Clement voiced for standardization of screw threads. His advocacy of following the standard system where every machine screw of a particular diameter would have a number of threads of a predetermined pitch and determined the number of threads for each diameter of the bolt.

When you look at the evolutionary process of pipe threading taps, you find that it was nearly 200 years ago, in 1828, that Joseph Clement, a British engineer, developed fluted screw-cutting taps and dies.

The Clement theory was carried forward by Joseph Whitworth. Whitworth greatly helped in standardizing the pipe threading taps. Given below is the gradual process of pipe threading taps:

Woodworking Tools: Widely popular in different parts of the world, including Egypt, Mesopotamia, Greece, and Rome, this type of tool continued to be used for a very long time. Woodworking tools continued to be used till the 17th century A.D. in watermills, flour mills, and windmills.

Metalworking Taps: It was at the beginning of the 18th century A.D. that metals, including iron, began to be used for creating pipe threads. For nearly 100 years, metalworking taps romped the scene of plumbing and other industrial works.

First Use of Mechanized Process: The discovery of lathe machines changed the scenario. In the middle of the 18th century, in 1751, Jacques de Vaucanson first developed an all-metal lathe machine. After 46 years, in 1797, Henry Maudslay invented the first screw-cutting engine, which we know today as the first metallic heavy lathe machine. This discovery marked the beginning of the Industrial Revolution in England. At the beginning of the 19th century, when Joseph Clement developed the fluted screw-cutting tap and died, the scenario changed.

Advanced Milling Practice: In the middle of the 19th century A.D. in 1860 and extending up to 1870, the advanced milling practice began in England, the USA, and other parts of Europe. The technique of thread cutting essentially became mechanical.

The Modern Mechanized Era: Today, pipe threading has become fully modern. You can also use advanced power taps, which can also be operated manually. You also have fully automatic mechanized ones, which are used for heavy-duty industrial purposes.

Conclusion

Tapping is the mechanical process of cutting or forming threads is used not only in plumbing and masonry but in almost every industry that uses metals. But centuries ago, there was a time when the old civilizations used their own threading and cutting tools made of hardwood, stone, and implements made of non-iron nature like copper and bronze. From the manual process using primitive tools, the pipe threading tap gradually became mechanized. But this process took hundreds of years.