Industries like pharmaceuticals, automotive, and food production handle all sorts of components, from aggressive chemicals to delicate ingredients that must be kept free from contamination. Indeed, highly resistant hoses are the unsung heroes of today’s world; nobody thinks of them while picking a perfectly crafted item from the grocery store, but when they malfunction, everybody suffers the consequences.

Not all industrial hoses are born equal, though, and they can come in a wide array of materials. Polyurethane, PVC, PFTE, rubber, and metal are some of the options available; each of them is recommended for specific tasks.

Overcoming a Tradition

Thermoplastics, rubber, and PVC have long dominated among industrial hoses, but only until better options emerged. Such traditional options aren’t resistant enough to stand demanding conditions while keeping their structural strength and flexibility. Advanced materials like TPE (thermoplastic elastomer) and PTFE (Polytetrafluorethylene) are the new standard in sectors like food & beverage, the auto industry, and chemical processing.

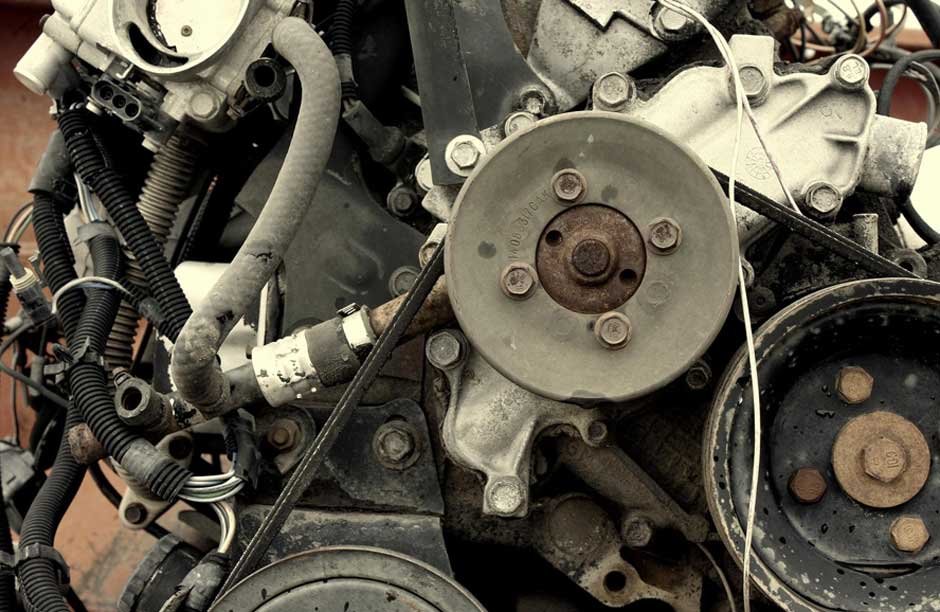

For instance, a convoluted ptfe hose is perfect for transferring chemicals across different parts of the production process. Its corrugated design ensures flexibility and resistance even in tight spaces. Such a hose can handle a vast array of chemicals and temperatures, being essential for food processing, and also for conveying steam and fluids.

PTFE is a compound more commonly known as Teflon. Teflon is the best material for tasks that demand high purity and great resistance, such as handling fuel and fluids in vehicles. Teflon is significantly superior to traditional options like rubber or PVC, which can swell and become brittle, thereby increasing the risk of leakage and contamination. This material is highly resistant to corrosion, ensuring the purity of the components that go through it.

A New Gold Standard

Indeed, convoluted PTFE hoses are the latest buzzword when it comes to durable, contamination-free, and highly resistant tubes for advanced fluid management solutions. Apart from the previously mentioned benefits of PTFE itself, its convoluted design makes it very easy to maintain. Thanks to their self-draining properties, these hoses are easy to clean.

Additionally, they offer an outstanding operating temperature range, maintaining their properties from -200ºC to 260ºC. More importantly, PTFE is considered an “inert” component, meaning that it doesn’t react to most chemicals. That’s why it can’t contaminate other substances or be contaminated by them.

Risks and Limitations

When it comes to industrial processes, there isn’t a one-size-fits-all solution. Teflon can be quickly degraded by molten alkali metals such as potassium or sodium, or by fluorinating agents like cobalt fluoride, caesium, and xenon difluoride. Otherwise, it’s the go-to option for several industrial processes, ranging from food production to fuel handling.

Fluid Dynamics of Success

Despite its few limitations, Teflon has become a benchmark in industrial hose production. It doesn’t matter if it’s for handling burning hot fuel, pristine chemicals for pharmaceutical production, or adding that delicious vanilla flavour to a beverage; there’s always a convoluted hose working backstage. More than a technical choice, it has become a strategic investment.