Introduction to Additive Manufacturing and 3D Printing

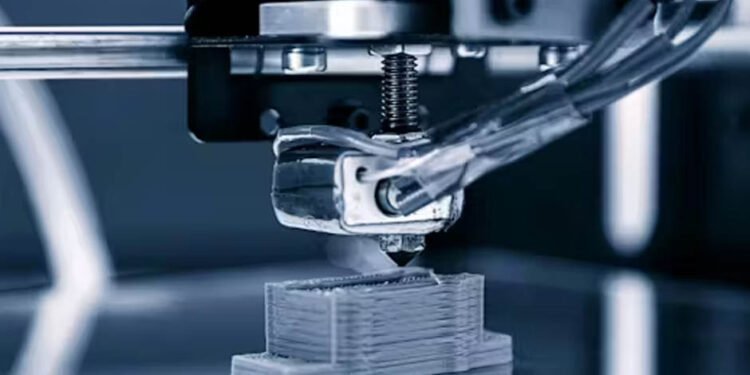

The process known as 3D printing, or additive manufacturing, is changing the way companies create and manufacture items. In contrast to conventional subtractive techniques, which involve removing material to form an object, additive manufacturing constructs objects layer by layer. This method decreases waste to a large extent and enables the production of intricate shapes that are challenging or impossible to make using conventional techniques. Companies increasingly turn to these additive manufacturing and 3D printing solutions to drive innovation and stay competitive in today’s fast-paced market. This shift enables businesses to bring products to market faster and cost-effectively, creating a more dynamic and responsive manufacturing landscape.

The Role of Additive Manufacturing in Business Growth

Implementing additive manufacturing can drastically transform business operations by enabling rapid prototyping and reducing time-to-market. This technology allows companies to quickly move from the initial design phase to produce a physical prototype, significantly cutting down the development cycle. This rate of speed is essential for staying ahead in sectors where being first to market can determine if a company thrives or fails. Moreover, additive manufacturing technologies can decrease production expenses by reducing material waste and eliminating the necessity for costly and time-consuming tooling setups. The flexibility in design promotes ongoing innovation, allowing businesses to provide their customers with more personalized and higher-quality products.

Advantages of 3D Printing for Different Industries

- Healthcare: In the healthcare sector, the ability to create custom prosthetics and implants that perfectly match an individual’s anatomy is groundbreaking. This customized method enhances patient results while decreasing recovery periods and the chance of complications. Moreover, using 3D printing enables the fabrication of surgical guides and anatomical models, assisting in preoperative preparation and education to enhance the overall standard of care.

- Aerospace: Aerospace companies benefit from additive manufacturing by producing lightweight yet durable parts. This enhances fuel efficiency and contributes to overall performance and safety. Creating complex geometries allows for the design of more efficient, high-performance components that can withstand extreme conditions. This, in turn, helps aerospace companies to meet stringent regulatory requirements and improve the reliability and lifespan of their products.

- Automotive: The automotive industry uses 3D printing for both prototyping and production of customized parts. This capability allows quicker innovation cycles and tailored solutions to meet specific needs. 3D printing facilitates the fast creation of prototypes for automotive engineers, which helps them test and improve their designs faster, resulting in higher-performing vehicles. Furthermore, producing custom parts as needed lowers inventory expenses and enhances the ability to offer clients tailored solutions.

Future Trends in Additive Manufacturing

The outlook for additive manufacturing appears bright, as new emerging trends are expected to boost business growth further. The progress in printing materials is broadening the opportunities for working with more vital metals and flexible plastics. Moreover, creating eco-friendly and long-lasting materials provides new possibilities for sustainable manufacturing. Moreover, there are high expectations for incorporating AI and ML technology in 3D printing to increase customization and efficiency. Businesses can use these technologies to develop products that cater to the specific requirements of their customers and are also more advanced. By keeping abreast of these advancements, companies can be ready to maximize the benefits provided by additive manufacturing.

How to Implement Additive Manufacturing in Your Business

- Identify the Need: Start by assessing how 3D printing can benefit your business, whether in prototyping, production, or customization. Understanding your specific needs will help you select the appropriate technology and strategy. Perform a comprehensive assessment of your current procedures to pinpoint areas where additive manufacturing can benefit most.

- Research Technologies: Different types of additive manufacturing technologies exist, each with strengths and weaknesses. Conduct comprehensive research to determine which technology best suits your business objectives. Consider elements like material suitability, speed of production, and the level of precision needed for your specific uses.

- Partner with Experts: Working with skilled experts can guarantee a seamless incorporation of 3D printing into your business practices. Professionals can offer helpful guidance and assistance during the execution phase, from choosing the appropriate machinery to streamlining your production processes. Search for collaborators with a demonstrated history of success in your field who can provide customized solutions to fulfill your particular requirements.

- Train Your Team: Proper training is essential to ensuring the successful implementation of additive manufacturing. Make sure your team has a strong understanding of the technologies and processes to maximize the advantages. Provide ongoing opportunities for growth and education to ensure your team remains informed on the most recent developments in the field.

Conclusion

As technology progresses, additive manufacturing and 3D printing are set to play an even more significant role in business innovation and expansion. These technologies provide a distinct advantage that is difficult to overlook, from cutting down on production expenses to allowing for the development of intricate and personalized designs. Staying informed about current trends and continuously addressing challenges enables businesses to successfully harness the potential of 3D printing in today’s competitive business environment. Utilizing these technologies will enhance operational efficiency and open up opportunities for innovation and growth across various industries.